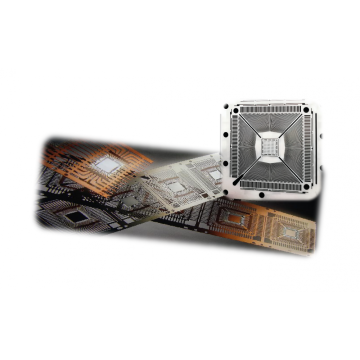

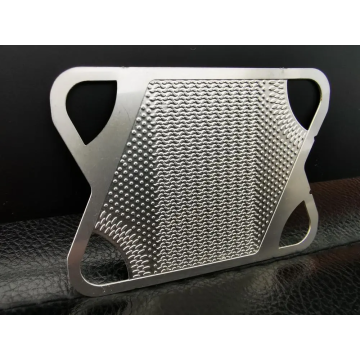

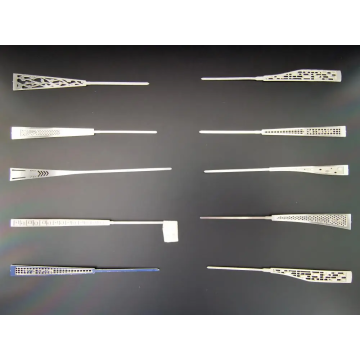

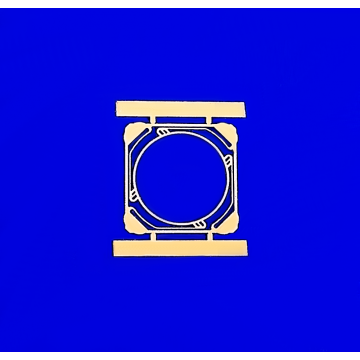

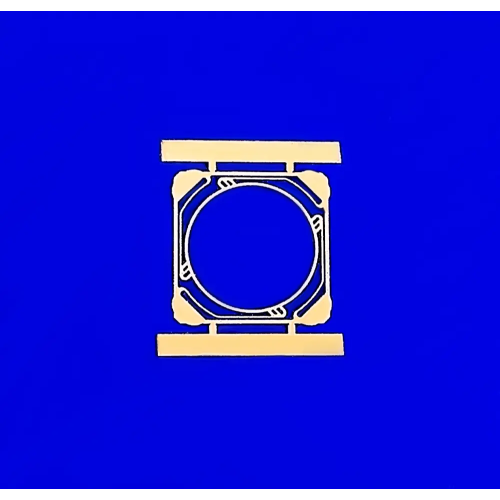

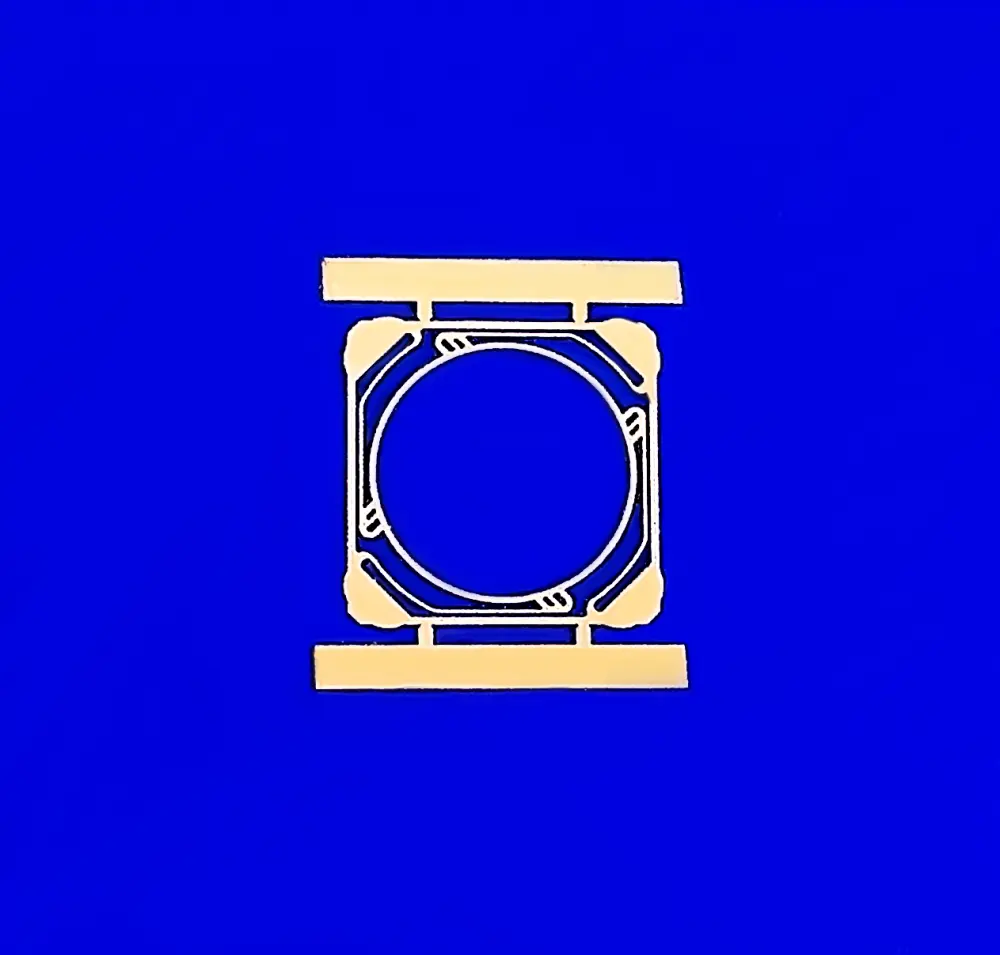

Computer Use Chemical Milling BF158-TM10 VCM Spring Sheet

- Min. Order:

- 2000 Piece/Pieces

- Min. Order:

- 2000 Piece/Pieces

- Transportation:

- Ocean, Air, Express

- Port:

- Ningbo, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | ISO9001:2015 / ISO14001:2015 |

| HS Code: | 8529904900 |

| Transportation: | Ocean,Air,Express |

| Port: | Ningbo,Shanghai |

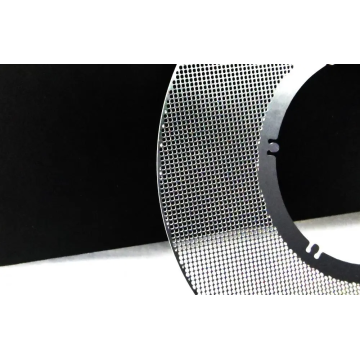

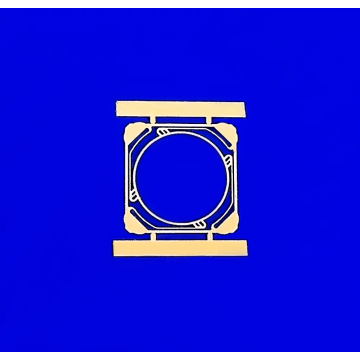

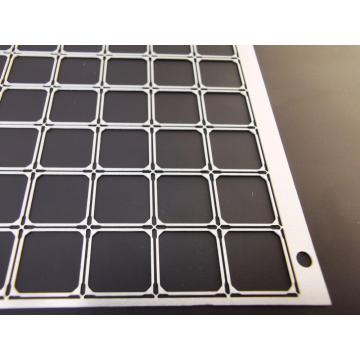

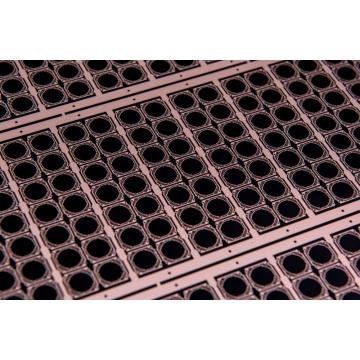

Computer Use Chemical Milling BF158-TM10 VCM Spring Sheet

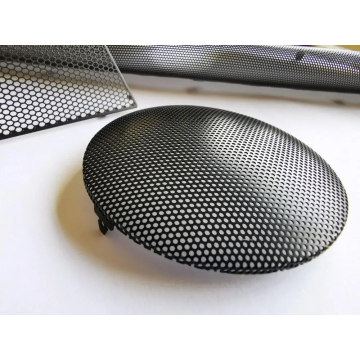

Chemical milling is a process used to selectively remove material from a metal surface using chemical etchants. It is commonly used in the aerospace and electronics industries to produce complex shapes and patterns on metal sheets.

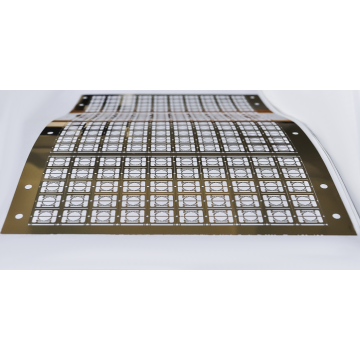

Our company specializes in etching process, and we also produce products similar to this process, like VCM Spacer, OLED Glass Cover, IC Lead Frame, and so on. If you are interested in these products, please send inquiry to us.

1. Low Power Consumption: VCM spring leaf can generate significant driving force at relatively low currents, reducing power consumption and energy consumption.

2. High-Efficiency Conversion: VCM spring leaf exhibits high energy conversion efficiency, converting input electrical energy into mechanical motion with minimal energy loss.

3. Silent Operation: The operation of VCM spring leaf is typically very quiet as it does not require traditional mechanical gear or belt transmissions.

4. Longevity and Reliability: VCM spring leaf is often made of high-quality materials, providing excellent durability and stability, ensuring reliable performance during long-term use.

5. Simplified Structure: VCM spring leaf features a relatively simple structure, reducing the number of components and parts, thereby contributing to reduced equipment weight and size. 6. Flexibility: VCM spring leaf can be custom-designed to suit different application requirements, making it suitable for various devices and systems.

7. Space Savings: The compact structure of VCM spring leaf helps save equipment space, especially in limited-space scenarios.

8. High Precision Drive: VCM spring leaf provides high-precision driving force in VCM drivers, enabling precise positioning and control suitable for applications requiring high precision motion.

9. Quick Response Time: VCM spring leaf has a rapid response speed, allowing for quick start, stop, and adjustments, effectively enhancing equipment performance and response time.

Related Keywords