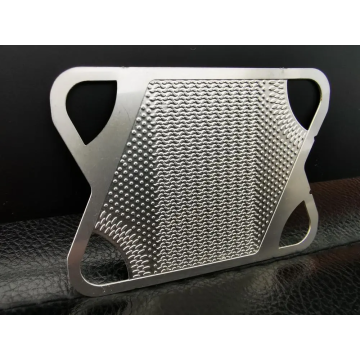

Customized Half Etching Metal Plate for Heat Exchangers

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Air, Express

- Port:

- Ningbo, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | ISO9001:2015 / ISO14001:2015 |

| Transportation: | Ocean,Air,Express |

| Port: | Ningbo,Shanghai |

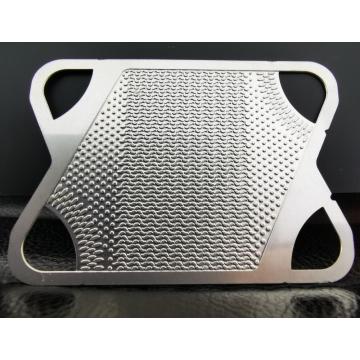

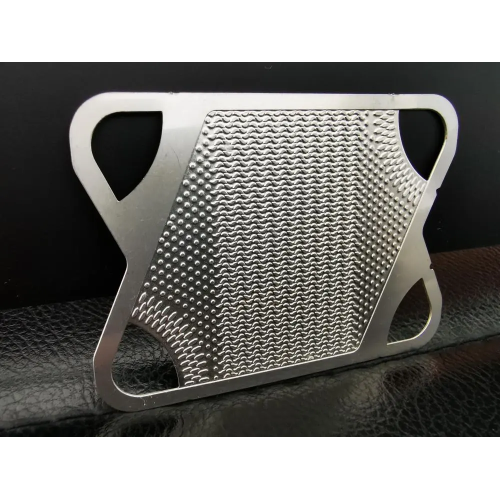

Customized Half Etching Metal Plate for Heat Exchangers

Half etching metal plates are commonly used in heat exchangers to enhance heat transfer efficiency. The half etching process involves selectively removing material from one side of the metal plate, creating a pattern of channels or grooves.

These etched channels increase the surface area of the plate, allowing for better heat transfer between the fluid flowing through the channels and the plate itself. The increased surface area also promotes turbulent flow, which further improves heat transfer.

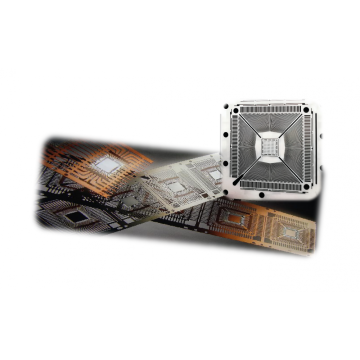

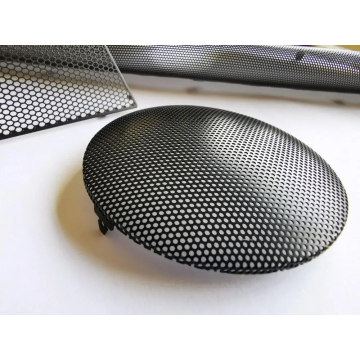

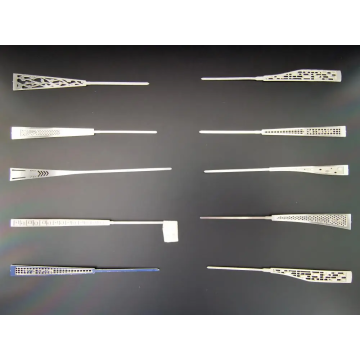

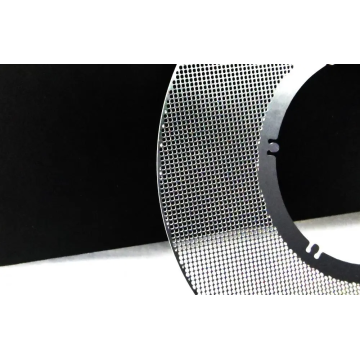

In addition to half etched metal products, we also have Others Etching Products, similar to IC Lead Frame for electronic products, Filter Mesh used for shower panel, Encoding Disk used displacement sensors for measuring the position of the shaft rotation angle, and so on. If you are interested in these, please send inquiry to us.

1. High-Efficiency Heat Transfer: The design and fluid distribution system of plate heat exchanger plates enable efficient heat transfer, enhancing heat energy utilization efficiency.

2. Compact Design: Plate heat exchanger plates adopt a plate structure, occupying a small footprint and saving space, making them particularly suitable for installations with limited space.

3. Flexible and Expandable: Plate heat exchangers can easily expand or reduce the number of plates to adjust heat transfer capacity according to specific requirements, adapting to different operating conditions.

4. Multiple Material Options: Plate heat exchanger plates can be made from various materials such as stainless steel, titanium, and nickel alloys to meet the heat transfer needs of different media.

5. High Strength and Pressure Resistance: Plate heat exchanger plates are manufactured with high-quality materials and craftsmanship, providing high strength and pressure resistance for safe and stable operation.

6. Easy Maintenance and Cleaning: The simple structure of plate heat exchanger plates allows for easy maintenance and cleaning, reducing maintenance costs and downtime.

7. Versatile for Various Fluids: Plate heat exchanger plates are suitable for heat transfer in both liquids and gases, making them applicable in various industrial sectors.

8. Environmentally Friendly and Energy Saving: The high-efficiency heat transfer and compact design of plate heat exchangers contribute to energy savings, promoting energy conservation and environmental protection.

9. Customization: Plate heat exchanger plates can be custom-designed to meet specific user requirements, catering to different industries and applications.

10. High Corrosion Resistance: Plate heat exchanger plates are made with corrosion-resistant materials, suitable for handling acidic, alkaline, and corrosive media.

Related Keywords