Customized Metal Etching Stainless Steel Encoder Disk

- Min. Order:

- 200 Piece/Pieces

- Min. Order:

- 200 Piece/Pieces

- Transportation:

- Ocean, Air, Express

- Port:

- Ningbo, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | ISO9001:2015 / ISO14001:2015 |

| Transportation: | Ocean,Air,Express |

| Port: | Ningbo,Shanghai |

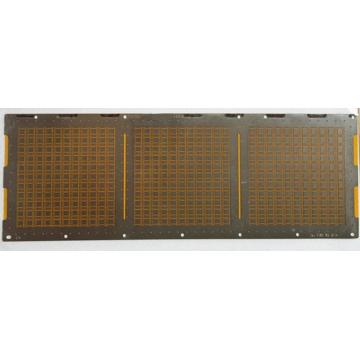

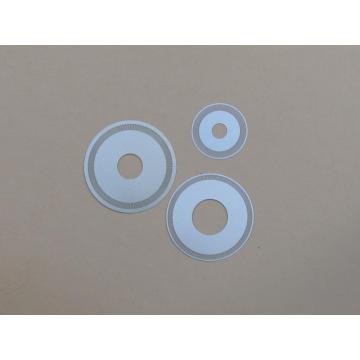

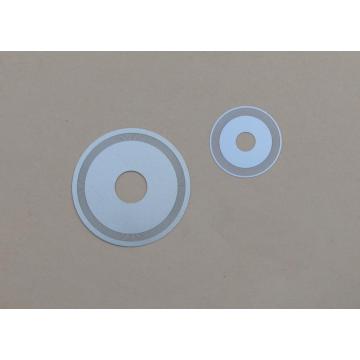

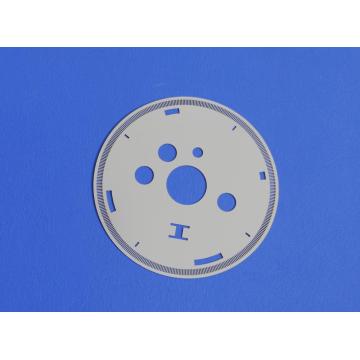

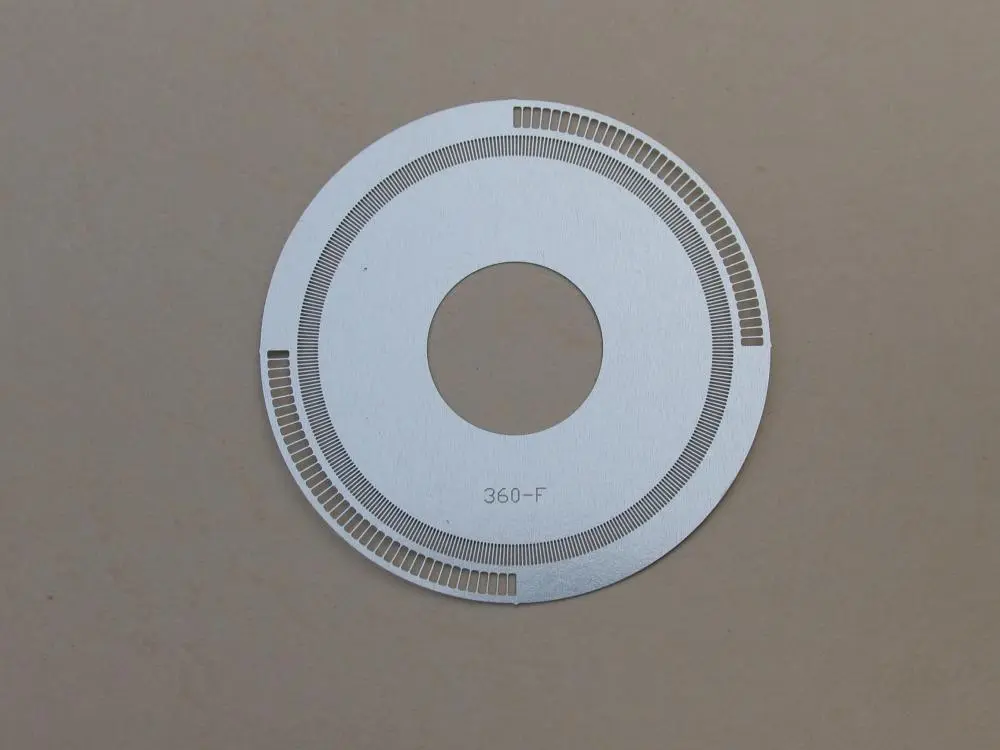

Customized Metal Etching Stainless Steel Encoder Disk

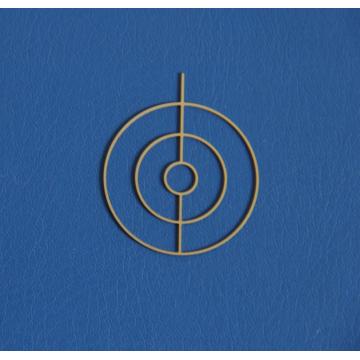

This precision etching Encoder Parts is a type of disk used in rotary encoders. It is made of a high-quality material, such as stainless steel or glass, and is etched with precise patterns or markings. These patterns are used to encode position or movement information in the encoder.

The etching process involves selectively removing material from the disk surface to create the desired patterns. This can be done using various techniques, such as chemical etching or laser etching. The patterns on the disk are typically arranged in a circular or spiral pattern, allowing the encoder to measure rotation or linear movement.

If you are interested in this or other Etching Products like IC Lead Frame, LCD TV Products for TV, Cleaning Blade for Printer and OLED Glass Cover for OLED screen, you can browse our website, any questions please contact us.

1. High Precision Measurement: Encoder gratings can achieve high-precision position and motion measurements, providing accurate position feedback suitable for applications with stringent precision requirements.

2. High Resolution: The high line count of the grating scale and the fine scale of the grating ruler grant it high resolution, allowing real-time capture of small position changes.

3. High Repeatability: Encoder gratings exhibit excellent repeatability, ensuring consistency and stability in measuring the same position.

4. Non-contact Measurement: The non-contact working principle between the grating scale and the sensor makes it immune to wear and friction, extending its lifespan.

5. Fast Response: Encoder gratings can respond in real-time to changes in position and motion, making them suitable for high-speed motion and real-time control scenarios.

6. High Reliability: The simple structure of the grating scale and its resistance to damage contribute to its high reliability and stability.

7. Multiple Type Options: Users can choose between absolute encoders or incremental encoders based on application requirements, catering to various application scenarios.

8. Adaptability to Different Environments: Magnetic gratings are suitable for harsh environments with high pollution, humidity, and temperature, expanding their range of applications. 9. Flexible Customization: Encoder gratings can be custom-designed according to specific application needs, meeting the functionality and performance requirements of particular applications.

10. Wide Range of Applications: Encoder gratings are widely used in mechanical manufacturing, automation control, measurement instruments, CNC machine tools, robots, and other fields.

Related Keywords