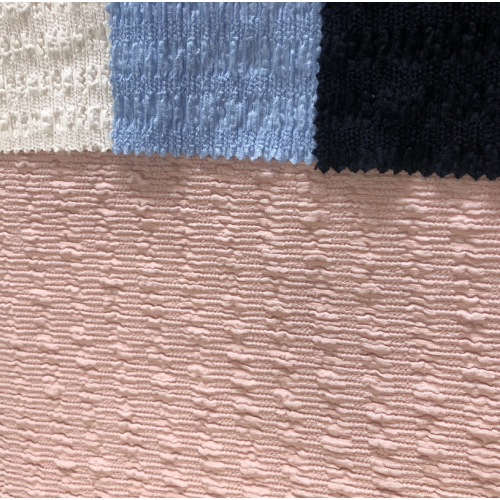

Bubble crease warp knitted jacquard

-

$2.00≥3000 Meter

- Min. Order:

- 3000 Meter

- Min. Order:

- 3000 Meter

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB |

| Transportation: | Ocean |

Crepe was conducted on the basis of the gauze, make its surface roughness has a longitudinal uniform wrinkles, this kind of cloth has a pretty cool soft tactility and good elasticity, at the same time also have special excellent permeability, crepe fabric is suitable for four seasons wear, after printing, color after processing of crepe can have a better visual experience, Suitable for the production of baby pajamas, dresses and casual clothing and other work clothes

Knitted fabrics are formed by stitching the threads together and can be divided into two types, weft and warp, according to the weaving method. Weft knitted fabrics, such as common sportswear, underwear, socks, and hand knitted fabrics, are woven laterally with weft yarns. Warp knitting is knitting all the needles at the same time. The structure, properties and production methods of warp knitted fabrics have the following characteristics:

1. Warp knitted fabric production efficiency, maximum machine speed up to 3600 RPM, door width 210 inches, efficiency up to 98%.

Warp knitted fabrics usually have a smaller elongation than weft knitted fabrics. Most weft knitted fabrics have a significant stretch in the transverse direction, whereas warp knitted fabrics have an extension of comb number and structure. Some warp knitted fabrics stretch both horizontally and vertically, but some fabric sizes. The stability is very good.

3. Warp knitted fabrics have good dissociation resistance. It can use different paper towels to reduce the weft knitted yarn breaks and holes caused by coil breakage.

4. Warp knitted fabric can be formed from different weft knitted yarns, so that different forms of network structure can be formed. The pattern change is simple, and almost all fabric can be woven.

In the production of mesh fabric, warp knitting technology is more practical than other production techniques. The mesh fabric produced can be of different sizes and shapes, and the fabric shape is stable and does not require any special finishing to make the fabric strong.

6. Warp knitting using a double stitch bed can produce molded products such as pantyhose, briefs, seamless tights and gloves.

Related Keywords