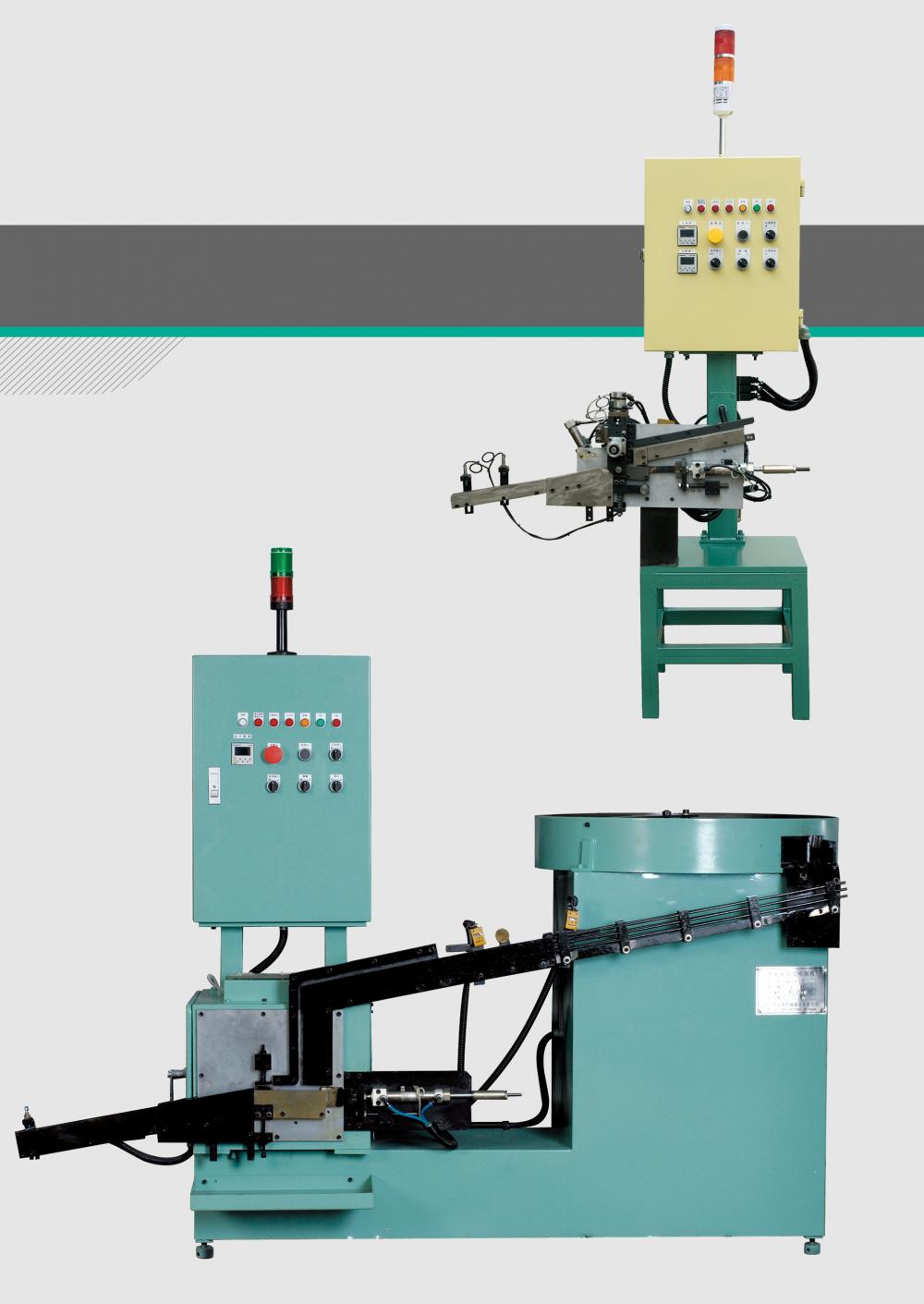

Bearing missing operation checking machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Ningbo, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean |

| Port: | Ningbo,Shanghai |

Bearings missing operation checking machine

The invention relates to Detect Miss Bearing Machine is Due to human or machine reasons, some products will miss the machining process. The utility model is characterized in that it includes a feeding raceway, a material storage groove, a pushing mechanism, a detection outer mold, a detection mechanism, a detection inner mold, a discharge raceway, a removal mechanism, etc. driven by the detection machine, Operation inspection machine is pressed in the detection outer mold and the detection inner mold to detect whether there is a problem of missing process of bearing. The Operation Inspection Machine invention replaces the manual detection of the missing process of the bearing ring, reduces the labor intensity of workers, improves the detection efficiency, and reduces the participation of people, Improve the reliability of detection. In order to improve the quality of products and prevent defective products from flowing to the market, an automatic detection method based on image processing technology is proposed. Through the image analysis and judgment of bearing ring, the automatic identification of defective products is realized. When used in enterprise production,Missing Operation Inspection Machine will effectively improve the efficiency and accuracy of product testing, so as to improve the economic benefits of enterprises.

Main technical parameters:

Inspction Size:Φ10-Φ100

Work Pressure:≥3.0Mpa

Power Voltage:380V

Inspection Cycle:1pc/s

Related Keywords