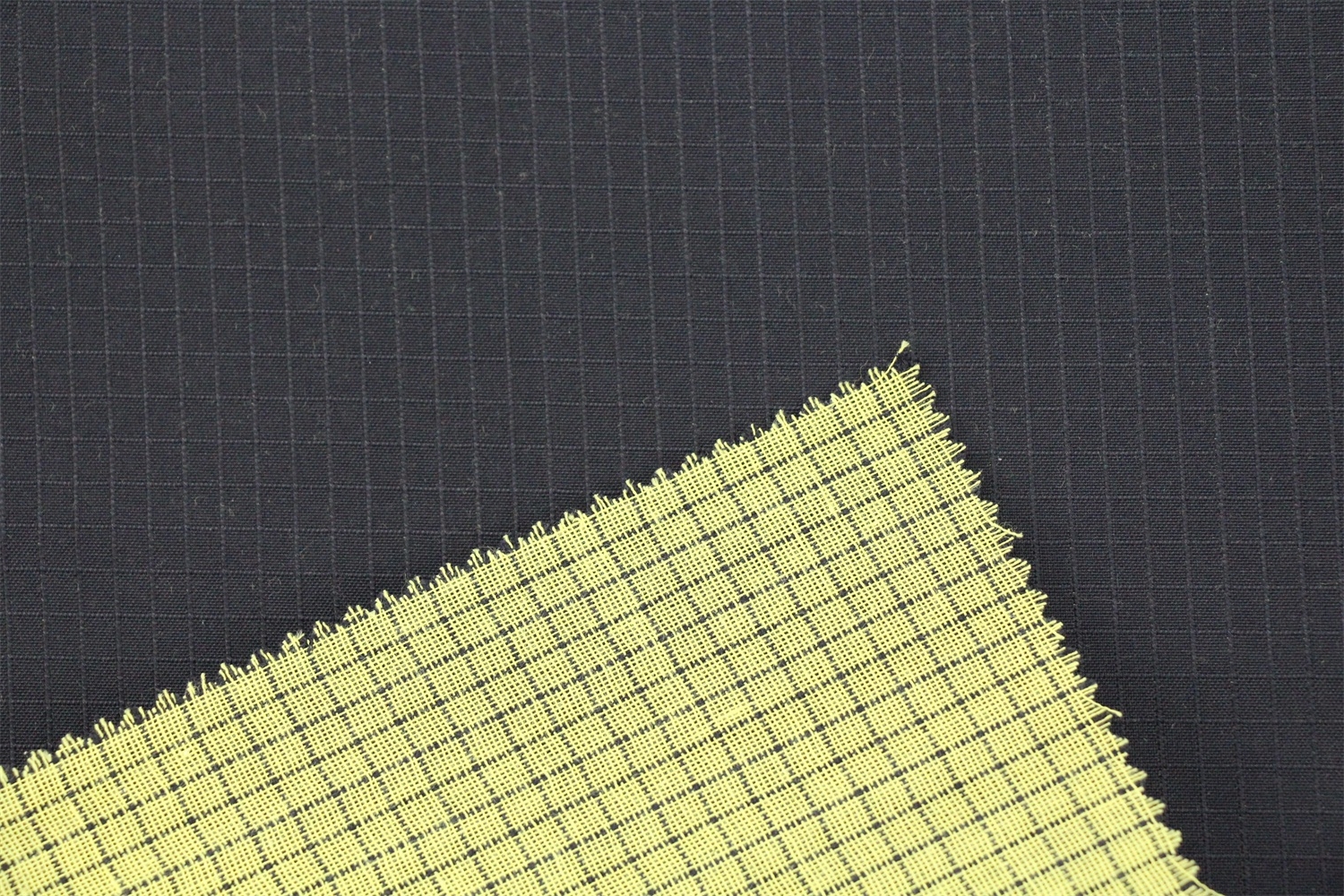

WR and FR Double-sided Dope Dyeing Aramid Fabric

-

USD16.6≥3000 Meter

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 3000 Meter

- Min. Order:

- 3000 Meter

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 30000000M/YEAR |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO9001,ISO14001,OEKO-TEX 100,OHSAS18001,ISO50001 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo |

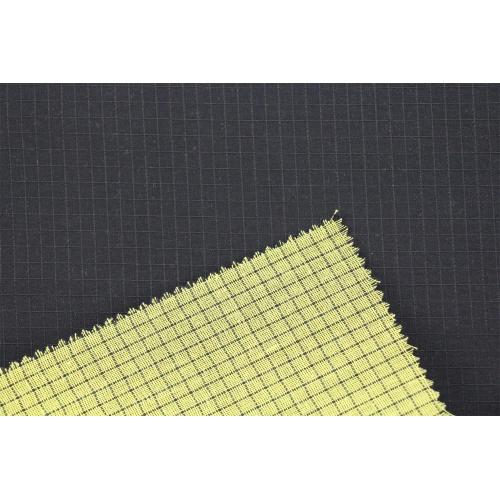

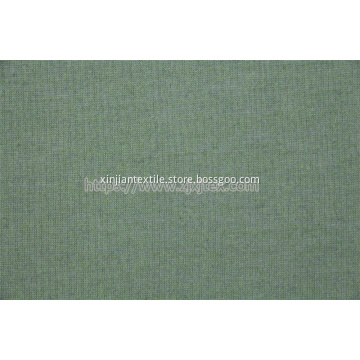

Water Repellent Flame Retardant Double-sided Dope Dyeing Aramid Fabric

Fabric Brief Specification:

This fabric is weaved by 100% aramid yarn.It has two sides.The front side is dope dyeing aramid yarn,color is orange.The back side is natural color aramid yarn.It's flame retardant and treated with waterproof.Both features is durable.

Company Profile

Zhejiang Xinjian Textile Inc. Ltd., established in 1951, is located in Shaoxing, Zhejiang, China. Last several decades, our enterprise has been focusing on R&D and manufacturing uniform fabrics and functional fabrics and regarding promoting their quality level in domestic market as duty.

Our enterprise owns four factories including weaving, dyeing, printing and yarn dyeing, which are equipped with about 300 sets of top-level equipment, automation systems and managerial system, having an advantage of a coordinated process of weaving, dyeing, printing, finishing, compositing and coating.

Our enterprise pays much attention to R&D ability. We own testing center and R&D center, which are equipped with national level instruments and softwares. And we cooperate with some research institutes and collages, especially with the General Logistics Department Quartermaster Equipment Research Institute. With their strong supports, our R&D ability stands on the top in China.

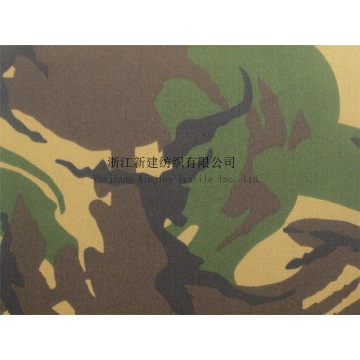

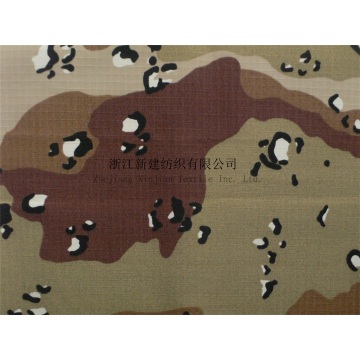

Since 1998, our enterprise has taken part in the whole process of researching, trail-producing, manufacturing new fabrics for Chinese military, Armed policed, Police security. We own rich technique and management experience of manufacturing multi-kinds of military fabrics and uniform fabrics. In domestic market, our enterprise not only serves for Chinese military, but also for a lot of large scale enterprises, such as SF-express, China Mobile, China Southern Power Grid, Deppon Express. And we export military fabrics to many countries in Europe, Southeast Asia, the Middle East and Africa. Honored as Top-priority Camo Fabric Chinese Manufacturer.

Weaving Workshop is equipped with spun warping and slashing producing line (Karl Mayer, Germany)and air jet loom producing line (Toyota,Japan). Annual production capacity reaches 30 million meters.

Dyeing and Finishing Workshop is equipped with overflow dyeing machines(AK, Taiwan), airflow dyeing machines (Monforts Fong`s,Hongkong), high temperature and high pressure jig dyeing machines (SUNG MOO, Korea), setting machines (Monforts, Germany),decating machines (KD, Italy), cropping machines(Lafer, Italy).calendering machines (KST, Germany), coating machines (SH Taiwan), and auto-weight batching and dispensing system (Kuans.Taiwan). Annual production capacity reaches 60 million meters.

Printing Workshop is equipped with singeing machine(Osthoff, Germany). desizing scouring bleaching combination machine(Benninger, Switzerland). mercerizing machine(Benninger Switzerland), continuous dyeing machine(Monforts Fong`s ,Hongkong),rotary screen printing machines(Stock,Netherlands, Zimmer Austria), ageing machine(Arioli Italy),soaping machine(Benninger Switzerland), and an auto-mixing system. Annual production capacity reaches 30 million meters.

Our enterprise, investing more than 10 million,builds up a R&D center and a testing center.The R&D center is equipped with whole set of national level weaving, dyeing, printing and finishing trail-producing instruments. The testing center is equipped with national level all kinds of textiles testing instruments.

Our enterprise has been owning the Certificate of ISO 9001 since 1996.

Our enterprise owns rich technique and management experience of manufacturing multi kinds of military fabrics and uniform fabrics.

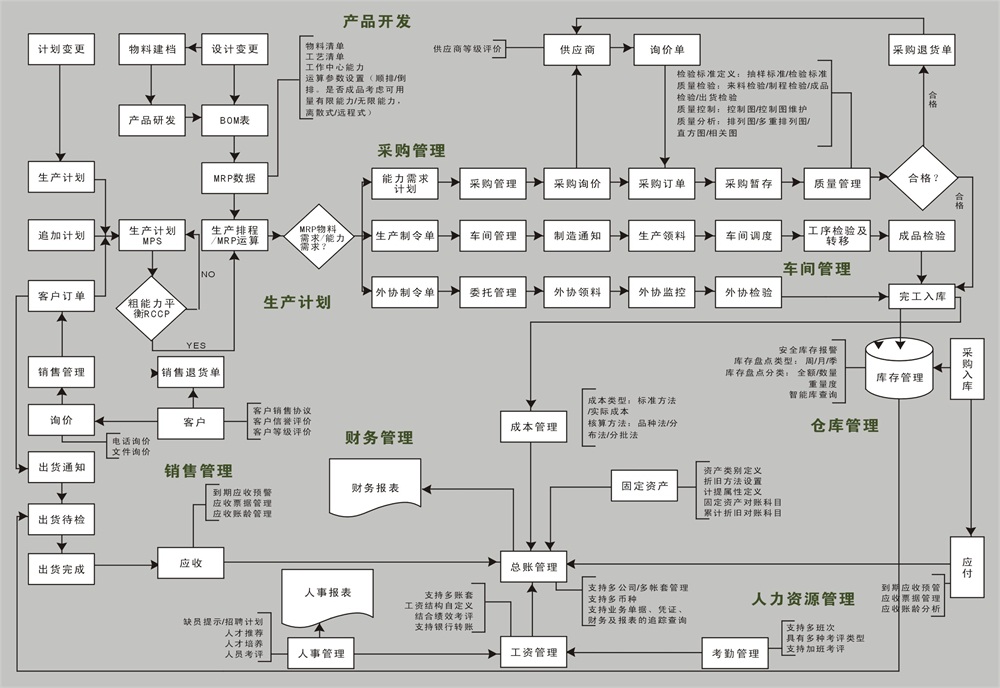

Our enterprise implements some automation systems and managerial system,such as ERP,auto-weight batching system.

Authenticated by ISO14001 and OEKO-TEX;

Authenticated by Chinese Energy System Certification

Clean Production Enterprise

Harmonious labor relations enterprise

All boilers are burnt with gas. Equipped with sewage treatment system and waste heat of sewage reclaiming system, treating 8 thousands tons per day; Equipped with offgas from setting machines treatment system;

In domestic market, our enterprise not only serves for Chinese military, but also for a lot large-scale enterprises, such as SF-express. China Mobile, China Southern Power Grid, Deppon express. And we export military fabrics to many counties in Europe, Southeast Asia, the Middle East and Africa. Honored as top-priority Camo Fabric Chinese Manufacturer.

Related Keywords