Textile Dyeing Roll Fabric Vacuum Packing Machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF, EXW, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 40 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Productivity: | 300set/Year |

|---|---|

| Supply Ability: | 300set/Year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | CE, ISO9001: 2000 |

Product Description

Product Description

TEXTILE DYEING ROLL FABRIC PACKING MACHINE

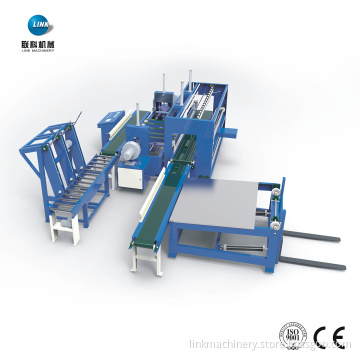

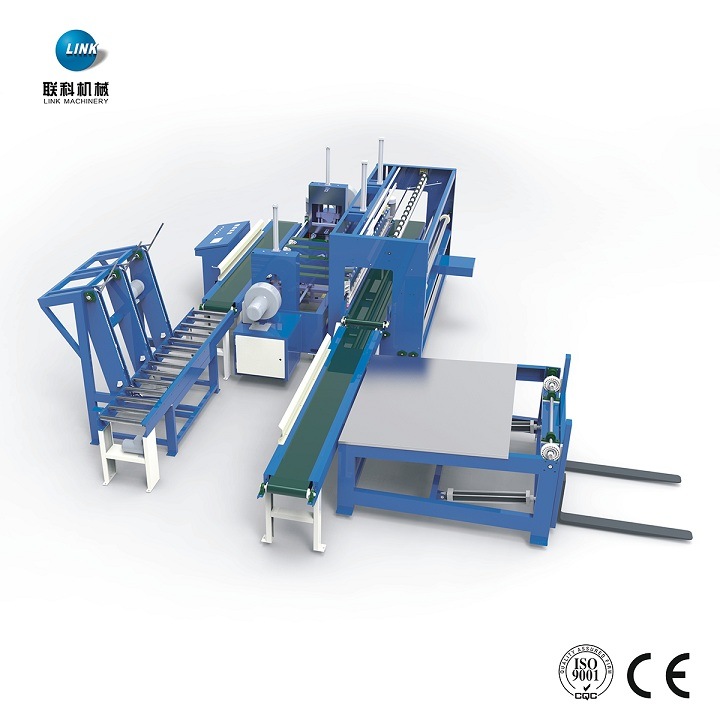

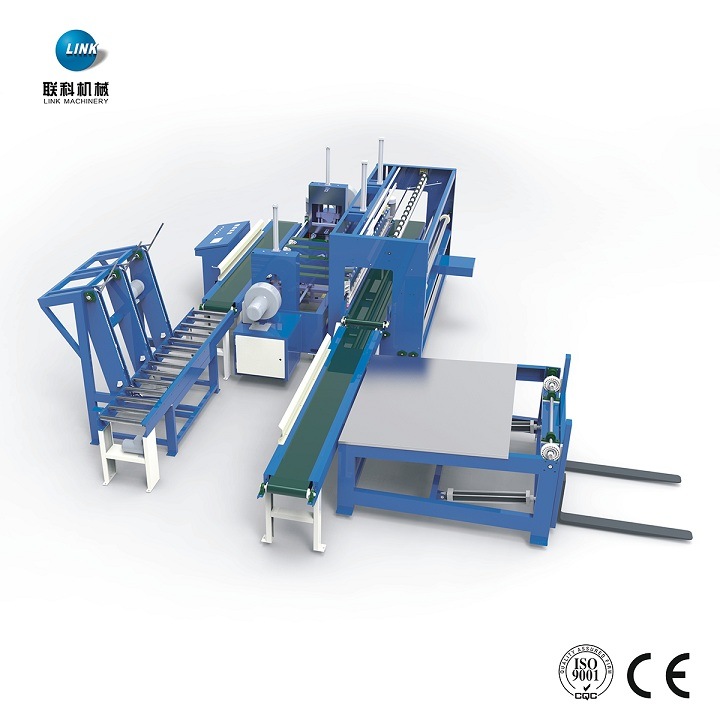

This packing type apply to the continuous packing for rolled cloth. It's configurated latest design cloth carts overturn device. Rolled cloth in cloth carts is poured to the cloth-storage table by hydraulic forklift and sent to the main machine by input conveyor according to detector. Packed roll is sent to cloth carts by climb device. So that save worker and reduce labor intensity and improve production efficiency.

Product parameter:

|

Model NO. |

LK-BZ-2800

|

|

Warranty

|

1 Year |

|

Condition |

New

|

|

Trademark |

LINK |

|

Transport Package |

PE Film and Wooden Pallet

|

|

Specification

|

L2740*W3140*H2360MM (customized)

|

|

Advantage |

Save Water, High Efficient, Connect with Stenter,Low Tension, Even Oil Removing, High Automation |

Technical parameters

machine mode:LK-BZ-2800

packing rate : 4-6 rolls/min

host machine size:L2740*W3140*H2360CM

packing size: roll diameter 100mm-500mm

PE film thickness:0.04-0.1mm

air pressure requirements: 6KG/CM3

packing technology: automatic color separation packing technology

Technical Instruction

01 The whole machine touch screen operation, controlled by PLC program, use high quality sensors, precisely control the process of input conveyor,packing, PE film hot shrinkage, trapping, climb, high position conveying, accurately falling.

02 The machine use intelligent automatic color separation control system. Packed rolls are sent to the appointed cloth carts by high position conveyor. Reduce the worker's labor intensity, avoiding errors.

03 Rolled cloth with different diameter can be automatic detected by latest infrared detector. Then machine adjust PE film conveyor according to roll diameter and precisely cutting and packing. So that efficiently save PE film consume.

04 The height of main seal blade and side seal blade can be precisely adjusted according to the roll diameter size, which can be detected by infrared detector. So that seal interface will be in the middle of roll and packed roll will look beautiful.

05 The machine configuration can be customized by special requirement and can choose automatic weighting device and labeling device, to reduce error from hand labeling and save laboring.

optional structure

01 Labeling machine: Can realize automatic print and stick label after connected with customer's ERP system.

02 Hot shrinkage device: This device apply to the hot shrinkage of PE film for packed roll, making packed roll tight and beautiful.

03 Overturn forklift device: This device apply to pour roll for the rolled cloth in the carts before sending to packing machine, saving laboring.

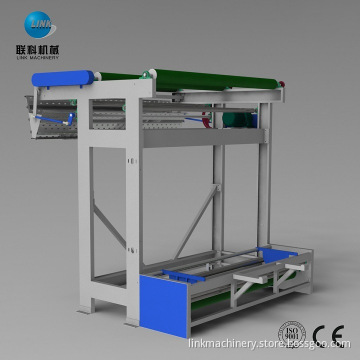

04 Climb device: This device apply to the packed roll that need to climb to the high position conveyor.

|

SARAH CHEN ZHEJIANG LINKE MACHINERY CO.,LTD FACTORY & OFFICE ADDR.:NO.318 YUEDONG NORTH ROAD, YUECHENG AREA, SHAOXING, ZHEJIANG, CHINA 312000 Tel:86-0575-89188008 Fax:86-0575-84780306 Web:www.zjlink.com.cn |

TEXTILE DYEING ROLL FABRIC PACKING MACHINE

This packing type apply to the continuous packing for rolled cloth. It's configurated latest design cloth carts overturn device. Rolled cloth in cloth carts is poured to the cloth-storage table by hydraulic forklift and sent to the main machine by input conveyor according to detector. Packed roll is sent to cloth carts by climb device. So that save worker and reduce labor intensity and improve production efficiency.

Technical parameters

machine mode:LK-BZ-2800

packing rate : 4-6 rolls/min

host machine size:L2740*W3140*H2360CM

packing size: roll diameter 100mm-500mm

PE film thickness:0.04-0.1mm

air pressure requirements: 6KG/CM3

packing technology: automatic color separation packing technology

Technical Instruction

01 The whole machine touch screen operation, controlled by PLC program, use high quality sensors, precisely control the process of input conveyor,packing, PE film hot shrinkage, trapping, climb, high position conveying, accurately falling.

02 The machine use intelligent automatic color separation control system. Packed rolls are sent to the appointed cloth carts by high position conveyor. Reduce the worker's labor intensity, avoiding errors.

03 Rolled cloth with different diameter can be automatic detected by latest infrared detector. Then machine adjust PE film conveyor according to roll diameter and precisely cutting and packing. So that efficiently save PE film consume.

04 The height of main seal blade and side seal blade can be precisely adjusted according to the roll diameter size, which can be detected by infrared detector. So that seal interface will be in the middle of roll and packed roll will look beautiful.

05 The machine configuration can be customized by special requirement and can choose automatic weighting device and labeling device, to reduce error from hand labeling and save laboring.

optional structure

01 Labeling machine: Can realize automatic print and stick label after connected with customer's ERP system.

02 Hot shrinkage device: This device apply to the hot shrinkage of PE film for packed roll, making packed roll tight and beautiful.

03 Overturn forklift device: This device apply to pour roll for the rolled cloth in the carts before sending to packing machine, saving laboring.

04 Climb device: This device apply to the packed roll that need to climb to the high position conveyor.

|

SARAH CHEN ZHEJIANG LINKE MACHINERY CO.,LTD FACTORY & OFFICE ADDR.:NO.318 YUEDONG NORTH ROAD, YUECHENG AREA, SHAOXING, ZHEJIANG, CHINA 312000 Tel:86-0575-89188008 Fax:86-0575-84780306 Web:www.zjlink.com.cn |

Related Keywords

Related Keywords

You May Also Like

You May Also Like