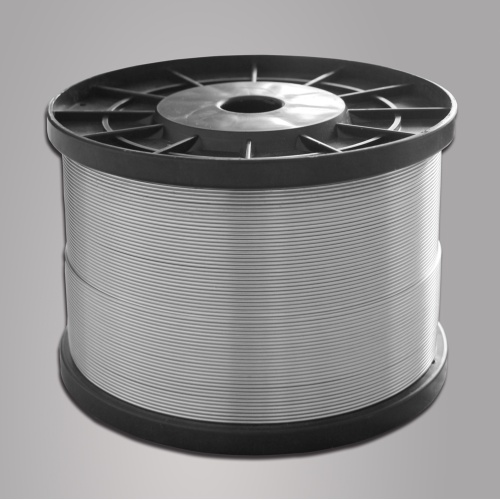

Sn90Zn10 for Film-Capacitor Metal-Spray

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- SHANGHAI, NINGBO

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | SHAOXING,CHINA |

|---|---|

| Productivity: | 60TON PER MONTH |

| Supply Ability: | 120TON PER MONTH |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | ISO9001 |

| HS Code: | 80030000 |

| Transportation: | Ocean,Land,Air |

| Port: | SHANGHAI,NINGBO |

The Sn90Zn10 Tin Zinc alloy wires have good mechanical strength and solderability. It can use for High-grade Film Capacitor Metal Spray ,with strong adhesion ability, and give capacitors good electrical performance such as reduced loss angle. They are complaint with EU RoHS and WEEE directives on lead-free electronic products, as well as the requirements of ISO 14000 system.

1. APPLICATION

THE WIRE COULD BE SPRAYED ON THE SURFACE OF FILM CAPACITORS

2. SPECIFICATION

2-1. APPEARANCE

THE WIRE MUST BE CHECKED THE CONDITIONS(CRACK, BURR, CORROSION & OTHER DEFECTS) OF THE SURFACE BY SIGHT, AS A DETERMINTAL TO USE.

2-2. DIAMETER : 1.1~3.2mm

DIAMETER(MM)

TOLERANCE

DIAMETER(MM)

TOLERANCE

1.1≤Ф≤1.65

+0.00~0.03

2.00<Ф≤2.30

+0.00~0.05

1.65<Ф≤2.00

+0.00~0.04

2.30<Ф≤3.20

+0.00~0.06

2-3. CHEMICAL COMPOSITIONS(%)

SPECIFICATION

MAIN INGREDIENT(%)

IMPUTIRY(%)≤

Sn

Zn

Pb

Cd

Fe

∑

HYSnZn10

89.00~91.00

9.00~11.00

0.04

0.002

0.012

0.05

HYSnZn15

84.00~86.00

14.00~16.00

0.04

0.002

0.012

0.05

HYSnZn20

79.00~81.00

19.00~21.00

0.04

0.002

0.012

0.05

HYSnZn30

69.00~71.00

29.00~31.00

0.04

0.002

0.012

0.05

HYSnZn40

59.00~61.00

39.00~41.00

0.04

0.002

0.012

0.05

HYSnZn50

48.00~52.00

48.00~52.00

0.04

0.002

0.012

0.05

HYSnZn60

38.00~42.00

58.00~62.00

0.04

0.002

0.012

0.05

HYSnZn70

28.00~32.00

68.00~72.00

0.04

0.002

0.012

0.05

HYSnZn75

23.00~27.00

73.00~77.00

0.04

0.002

0.012

0.05

HYSnZn80

18.00~22.00

78.00~82.00

0.04

0.002

0.012

0.05

2-4. PHYSICAL PROPERTIES & MECHANICAL PROPERTIES

MELTING POINT : 198~395℃

GRAVITY : 7.0~7.3 g/cm2

ELONGATION(%) : ≥20 A100mm(%)

TENSILE STRENGTH : ≥60 Rm(N/mm2)

VOLUME RESISTIVITY: ≤115 mΩ.mm2/m at 20℃

Related Keywords